Introduction

With the recent update to our Online Quote Tool, you can now upload, view and order your .step and .3mf files. In this blog post, we’ll discuss what these file formats are and delve into their unique characteristics, benefits, and their roles in the 3D design and printing world.

Understanding .step Files:

Definition:

The .step file, an acronym for Standard for the Exchange of Product Data, is a versatile and widely recognised file format used primarily for CAD data interchange between users, software applications, and systems. Its name reflects its primary goal: facilitating seamless exchanges of product information.

Encoding Method:

.step uses constructive solid geometry (CSG) or boundary representation (B-Rep) or both to represent 3D data. This allows it to carry more comprehensive data about the object, including colour, assembly structures, and other metadata.

Advantages of .step:

One of the main strengths of .step files lies in their ability to encapsulate not just geometric data but also assembly structures, colour information, and other crucial metadata. Unlike the more simplistic .stl files, .step files retain a model's parametric data, making detecting and rectifying design anomalies easier.

Popularity in Design Engineering:

Given its comprehensive nature, .step has carved out a significant space for itself in various industries. Especially in fields like product design and mechanical engineering, it's favoured because of its holistic representation of 3D objects. The level of detail it offers provides a more profound insight into designs, making it invaluable for processes where intricate nuances matter and precision is paramount.

Understanding .stl Files:

Definition:

The .stl file, short for stereolithography, has its origins tracing back to the early days of 3D printing. Designed primarily for the 3D printing process, it describes the surface geometry of three-dimensional objects without representing colour, texture, or other common CAD model attributes.

Encoding Method:

.st files use triangles to represent the surface geometry of a 3D object. It’s essentially a collection of triangular facets. Each facet is defined by a normal and three points representing the triangle's vertices. This simple structure allows for a clear representation of the shape but not of the other attributes of the 3D object.

Why .stl for 3D Printing?:

The .stl format has become a benchmark in the 3D printing industry primarily due to its simplicity. At its core, a .stl file breaks down objects into a series of triangular facets. This simplicity ensures that the file can focus solely on the model's geometry, making it universally compatible with a wide array of 3D printers and slicing software. The format's adaptability and straightforwardness make it the go-to for most 3D printing applications.

Limitations:

.stl files are non-parametric "dumb" solids, limiting their editability and making design alterations or repairs challenging. They depict 3D objects using a triangular mesh, where mesh fineness dictates resolution and file size. A coarse mesh may compromise design fidelity, especially in intricate designs, while an overly detailed mesh can inflate the file size without substantial gains in print quality, potentially slowing processing and transfers.

Understanding .3mf Files:

Definition:

The .3mf (3D Manufacturing Format) file is a modern, versatile format developed to eliminate the complexities and interoperability issues of other 3D printing file formats. It was created to serve as a universally accepted format for 3D printing, containing detailed information about the model, including colours, textures, and other metadata.

Encoding Method:

.3mf uses XML-based structures to represent 3D data. This allows for more efficient data representation in certain scenarios compared to .stl’s verbose way of specifying every triangle. Redundancies can be reduced, and only the necessary details need encoding. Pretty smart stuff!

Advantages of .3mf:

Unlike .stl files, which primarily focus on geometry, or even .step files, which capture assembly and colour data, .3mf was crafted with 3D printing in mind. This means it can retain intricate details like multiple materials, full-colour printing data, and more, all in a single, compact file. Its all-encompassing nature ensures that the user's design vision is entirely preserved.

Rising Popularity:

Though newer than the other formats, .3mf is quickly gaining traction within the design and 3D printing communities due to its advanced capabilities, streamlined structure, and robustness in capturing the nuances of a design.

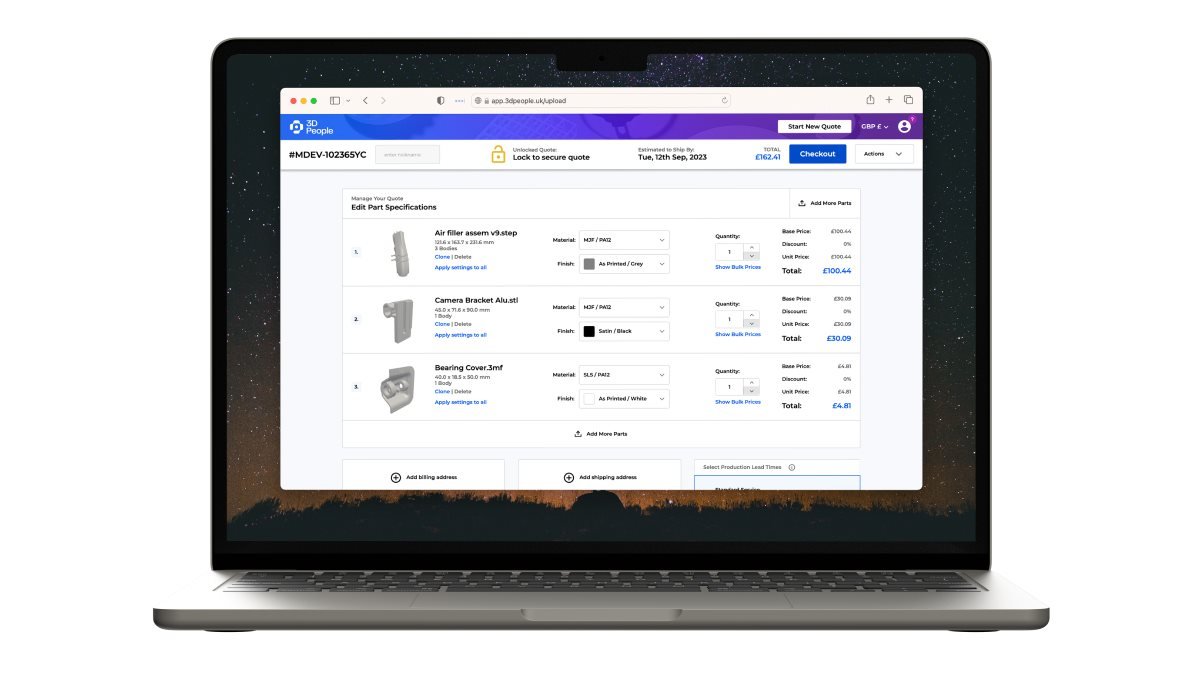

Bridging the Gap with Our Online Quote Tool:

Adapting to Diverse Formats:

In the multifaceted realm of 3D design, each file format brings its unique strengths. Recognising this, our updated Online Quote Tool accepts both .step and .3mf files alongside the industry-standard .stl. Our intention is to provide maximum flexibility to designers, engineers and makers, understanding that each project might demand a different approach and format.

Prioritising Original Design Integrity:

While visual previews might lean on the universally accepted .stl format, the real value for us lies in the original data that you upload, regardless of the format. This means that whether you upload a .step, .3mf, or .stl, our commitment is to honour the depth, precision, and intricacies of your design. When it comes down to manufacturing, it's this richness in your original file that guides our production process.

Conclusion:

Navigating the realm of 3D printing can be intricate, with file formats playing a pivotal role in shaping the design-to-manufacturing journey. This exploration into .step, .stl, and .3mf files underscores their unique attributes and significance in the 3D design landscape. With our updated Online Quote Tool, we strive to simplify this journey for you. By embracing diverse file formats, we ensure that your design's intricacy and authenticity remain uncompromised. As the 3D printing industry evolves, we remain committed to providing tools that prioritise your design's integrity, bridging the gap between intricate design requirements and seamless production. Through this approach, we aim to bolster the synergy between designers, engineers, makers, and manufacturers, ensuring that your vision is translated into tangible reality with precision and fidelity.

If you’ve not already, try out our updated Online Quote Tool. Dive in and explore the newly integrated features for a more comprehensive 3D printing journey. And as always, your feedback is our compass. Share your thoughts, experiences, or suggestions, and let's shape the future of 3D printing together!